Research projects

CHEOPS

CHEmistry Of Primary Systes

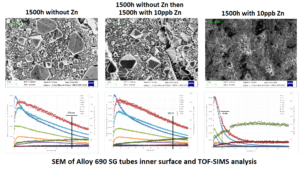

The aim of this project is to improve the fundamental understanding of the primary system,

and in particular the behavior of the several chemical species in the primary circuit from source to sink.

The project includes modelling studies and experimental studies through tests on MAI experimental loops (BOREAL, TITANE, ZINC and SOLO facilities).

The technical objectives of the project are:

- have a better control of corrosion and release into the reactor coolant system (e.g., from steam generator tubes);

- work on thermochemistry and speciation to provide reliable input database;

- have a better knowledge of Zinc impact;

- determine how local, time-dependant chemistry conditions influence colloid and particle formation, growth, and thus : deposition and radiation field;

- work on radiolysis phenomenon.

Contact:

![]() Bruna MARTIN-CABANAS

Bruna MARTIN-CABANAS

![]() +33 (0) 1 60 73 66 50

+33 (0) 1 60 73 66 50

![]() bruna.martin-cabanas@edf.fr

bruna.martin-cabanas@edf.fr

CISTERN

Civil Structure Engineering Resilience for Nuclear 3

MAI, EPRI and CGN are collaborating to perform joint research on civil engineering (CE) structures. This work is quickly showing its relevance to the industry, particularly in the area of long term operation (LTO). The primary objective of this research is twofold: to address regulatory concerns about ageing civil infrastructure and its integrity for LTO and to minimize unanticipated operational events. The research program includes actions concerning:

- Chemical evolution of concrete in NPP. The prediction of concrete properties from the mix, the assessment of the evolution of concrete properties under attack by underground water, and the testing of bio-healing techniques to improve concrete leak-tightness are addressed.

- Detection and mitigation of reinforcement corrosion. Different techniques for the assessment of corrosion kinetics in the lab and on the field are tested or designed, and cathodic protection and electrochemical chloride extraction are investigated.

- Defect and aging detection in concrete structures. NDE techniques are assessed to detect construction defects or corrosion of embedded liners. These detection methods are also modelled. Innovative strain measurement techniques are also proposed, and automatic defect and change detection from drone images are investigated.

- Ageing of plain and reinforced concrete under temperature and humidity loadings. The long-term evolution of concrete properties under temperature and humidity loadings is investigated, as well as the progress of carbonation and corrosion under the same type of conditions.

Contact:

![]() Jean-Luc ADIA

Jean-Luc ADIA

![]() +33 (0) 1 60 73 60 84

+33 (0) 1 60 73 60 84

![]() jean-luc.adia@edf.fr

jean-luc.adia@edf.fr

CORDEE

Chemistry Corrosion, Deposits and fouling in the Secondary Circuit

Iron oxides, as the main compounds of corrosion products in the secondary circuit of pressurized water reactors (PWRs), are known to be involved in many phenomena. In particular, these corrosion products, mainly derived from the general corrosion and flow assisted corrosion of carbon steel equipment upstream of steam generators (SG), can be transported to the latter where they can accumulate as a result of diphasic functioning of SG and participate in deposit formation. Depending on their location, the deposits lead to the fouling of the free surface of the SG tubes, the clogging of broached holes of the tubes support plates or the formation of hard sludge at the bottom of the SG on the tubes sheet. The consequences, which are usually a decrease in the efficiency of thermal transfer, a disturbance of the diphasic fluid flow and in some cases a risk of rupture of SG tubes, are managed by costly maintenance operations such as chemical cleanings.

Iron oxides, as the main compounds of corrosion products in the secondary circuit of pressurized water reactors (PWRs), are known to be involved in many phenomena. In particular, these corrosion products, mainly derived from the general corrosion and flow assisted corrosion of carbon steel equipment upstream of steam generators (SG), can be transported to the latter where they can accumulate as a result of diphasic functioning of SG and participate in deposit formation. Depending on their location, the deposits lead to the fouling of the free surface of the SG tubes, the clogging of broached holes of the tubes support plates or the formation of hard sludge at the bottom of the SG on the tubes sheet. The consequences, which are usually a decrease in the efficiency of thermal transfer, a disturbance of the diphasic fluid flow and in some cases a risk of rupture of SG tubes, are managed by costly maintenance operations such as chemical cleanings.

The new MAI CORDEE 3 project aims to meet high expectations of plant operators in terms of availability, safety and performance of the secondary circuit. The main objectives of this project are:

- To prevent SG performance loss by controlling deposit phenomena.

- To simplify current conservation methods of the secondary circuit using film forming substances.

- To identify and validate alternative chemical conditioning or technology to replace CMR (carcinogenic, mutagenic or toxic for reproduction) products.

Contact:

![]() Adèle ASTORG

Adèle ASTORG

![]() +33 (0) 1 60 73 65 54

+33 (0) 1 60 73 65 54

![]() adele.astorg@edf.fr

adele.astorg@edf.fr

CSI (Corrosion Scene Investigation)

To predict PWSCC kinetics of components

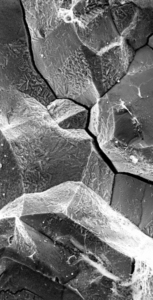

CSI project aims to predict kinetics of stress corrosion cracking (SCC) in components exposed to the primary water: Bottom Mounted Instrumentation Nozzles, Vessel Head Penetration, Steam Generator divider plates, bolts…

The materials concerned are austenitic Ni alloys (alloys 600/182/82, alloys 690/152/52), cold worked or aged stainless steels (AISI 304L/316L), and high strength alloys for boltings.

In order to increase the predictability of engineering models, efforts will be put in order to:

- Develop physic-based models (deformation, oxidation, failure) rather than empirical ones,

- Validate models from mock-ups characterization and SCC lab tests,

- Develop numerical tool for application of SCC models at the scale of large components.

CSI deliverables will allow the end-user to perform rapid and reliable evaluation of SCC risk of primary circuit components. Deliverables will be used to:

- Better explain observed degradation to anticipate the future ones

- Optimize inspection frequency

- Evaluate mitigating methods

Contact:

![]() Claire RAINASSE

Claire RAINASSE

![]() +33 (0) 1 60 73 74 94

+33 (0) 1 60 73 74 94

![]() claire.rainasse@edf.fr

claire.rainasse@edf.fr

MANDENA

MANDENAMANDENA is devoted to the development and validation of NDE modeling codes as applied to the detection of defects in increasingly complex materials and component geometries.

To deal with these issues, EDF R&D is developing specific codes for each of the three main NDE methods applied in nuclear plants: ATHENA for ultrasonic inspection, MODERATO for radiographic inspection and C3D for eddy current inspection.

The code development in MANDENA will be supported by EDF R&D and the experimental validation will be conducted by EPRI.

The purpose of NDE is to provide data to verify the lack of critical flaws in the nuclear power plant components. NDE allow for assessing the integrity of the primary and secondary circuits, and contributes to defense in-depth of nuclear power plants.

Contact:

![]() Pierre-Emile LHUILLIER

Pierre-Emile LHUILLIER

![]() +33 (0) 1 60 73 66 45

+33 (0) 1 60 73 66 45

![]() pierre-emile.lhuillier@edf.fr

pierre-emile.lhuillier@edf.fr

FRACTIGUE

Fracture & Fatigue – Methods, Experiments & Tools for Structural Integrity Assessment

This project is focused on the Structural Integrity assessment of Nuclear Power Plants relative to fatigue and fracture mechanics of metallic component.

FRACTIGUE project is the follow-up of the MODERN and the main contributors to the project are EDF, CGN and CEA.

The objectives are to:

- Develop and consolidate Methods and criteria for crack initiation in air and in PWR environment

- Evaluate the need to modify fatigue crack propagation codification

- Validate advanced methods for ductile fracture

- Develop numerical methods for fatigue evaluation

Contact:

![]() Laurent DUTRECH

Laurent DUTRECH

![]() +33 (0) 1 78 19 37 93

+33 (0) 1 78 19 37 93

![]() laurent.dutrech@edf.fr

laurent.dutrech@edf.fr

POLYAGE

POLYmer AGEing

Due to some of their particular properties as flexibility or insulation, polymers are widely used in nuclear power plants. As all the materials, polymers are sensitive to their environment. If qualification tests, which include some ageing tests, ensure a good quality of the polymers installed, they fail to predict a lifetime or to provide information useful to establish an ageing management strategy of the components.

This project aims to improve the polymer ageing strategy management in NPPs through:

- The identification and modelling of chemical ageing mechanisms of polymers as a function of their formulation and for different ageing factors,

- The development and validation of an associated numerical tool of polymer ageing simulation and its dissemination to MAI members,

- The definition of protocols and relevant criteria on micro sample and non-destructive exams to monitor polymer ageing,

- A database of experimental results on polymers studied.

The value assessment of this project is related to avoided costs:

- On cables by providing ageing management tools to justify to the regulators the cable condition and calculate residual lifetime to avoid costly and technically complicated cable replacements,

- On other equipment, they will allow to relieve the stresses of replacement and reduce maintenance costs.

Contact:

![]() Sarah CHATENET

Sarah CHATENET

![]() +33 (0) 1 60 73 72 61

+33 (0) 1 60 73 72 61

![]() sarah.chatenet@edf.fr

sarah.chatenet@edf.fr

RPV INTEGRITY

Reactor Pressure Vessel Lifetime

One of the key issues concerning RPV Integrity is the radiation effect on the RPV steel in the core zones. The vessel steel becomes more brittle in the RPV core region where radiation is high. Margins have been included at design and manufacturing stages taking into account the irradiation embrittlement of the materials. Moreover, operating measures have been taken to manage RPV ageing. The challenge is to preserve margins and to provide the safety cases supporting these margins.

One of the key issues concerning RPV Integrity is the radiation effect on the RPV steel in the core zones. The vessel steel becomes more brittle in the RPV core region where radiation is high. Margins have been included at design and manufacturing stages taking into account the irradiation embrittlement of the materials. Moreover, operating measures have been taken to manage RPV ageing. The challenge is to preserve margins and to provide the safety cases supporting these margins.

The RPV Integrity project (2014-2017) is focused on material and mechanical issues. The objective is to provide tools and data for the demonstration of the safe operation of the reactor pressure vessel significantly beyond 40 years of operation.

The project deals with embrittlement and integrity assessment issues. Special attention is given to the understanding of thermal and irradiation induced ageing of RPV materials. Mechanical understanding for modelling of crack initiation and propagation is also a major concern in order to improve integrity assessment models. This project helps to increase confidence in RPV integrity assessment models by each partner by showing use of common approaches and sharing experimental data supporting the mechanical models.

Contact:

![]() Vincent LEFEBVRE

Vincent LEFEBVRE

![]() +33 (0) 1 30 87 90 81

+33 (0) 1 30 87 90 81

![]() vincent.lefebvre@edf.fr

vincent.lefebvre@edf.fr

LOWEAR GUIDE

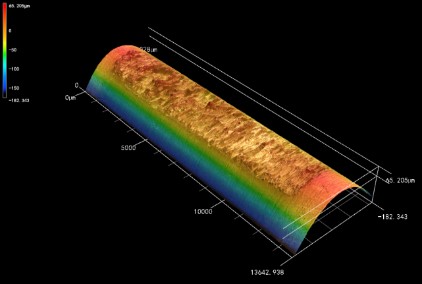

Investigations of fretting wear mechanisms and lifetime prediction of Inconel 690 Steam Generator tubes

Wear is likely to become the predominant life limiting phenomenon for steam generator tubes made of alloys 690. The first objective of the lowear guide project is to have a better estimation of wear kinetics of 690 alloy Steam Generator tubes wearing against anti-vibration bars (AVBs). The second objective of the Lowear guide project is to understand better wear mechanisms.

Wear is likely to become the predominant life limiting phenomenon for steam generator tubes made of alloys 690. The first objective of the lowear guide project is to have a better estimation of wear kinetics of 690 alloy Steam Generator tubes wearing against anti-vibration bars (AVBs). The second objective of the Lowear guide project is to understand better wear mechanisms.

To answer this objective, wear experiments of different durations with 690 tubes are performed by CGN SNPI and AREVA, followed by wear volume measurements and metallurgical analyses to assess wear kinetics and mechanisms.

Contact:

![]() Rémy BONZOM

Rémy BONZOM

![]() +33 (0) 1 60 73 74 19

+33 (0) 1 60 73 74 19

![]() remy.bonzom@edf.fr

remy.bonzom@edf.fr

VESSEL INTERNAL PROJECT

Ageing of Lower Core Internals Components

The functions of the internal components of PWR vessels are to position and support the core and provide a metered control of reactor coolant flow into each fuel assembly by canalizing the fluid. Moreover, the lower core internals contributes to the neutron protection of the reactor pressure vessel by absorbing most of the neutron flux from the core. The internals lifetime has an important impact on the nuclear power plant lifetime because of the cost and difficulty of their replacement.

The functions of the internal components of PWR vessels are to position and support the core and provide a metered control of reactor coolant flow into each fuel assembly by canalizing the fluid. Moreover, the lower core internals contributes to the neutron protection of the reactor pressure vessel by absorbing most of the neutron flux from the core. The internals lifetime has an important impact on the nuclear power plant lifetime because of the cost and difficulty of their replacement.

The MAI Vessel Internals Project seeks to consolidate calculation methodologies and focus on swelling as well as other ageing mechanisms. It focusses on Loading calculations, Void Swelling, and IASCC. The specific objectives of the MAI Vessel Internals Project 2015-2019 determine the structure of the project.

Each major objective is studied in a work package.

The major work packages of INTERNALS are:

- Loading Calculations: Validate the neutronics and thermal calculation models through a benchmark approach (heavy reflector, sensitivity analysis) and experimental validations.

- Void Swelling: Assess the swelling mechanisms due to irradiation of austenitic stainless steels constitutive of the Lower Core Internal structures (baffle plates, formers, baffle bolts, core barrel, core barrel bolts,…) in PWR conditions.

- Microstructure Analysis: Improve our physical-based understanding of irradiation induced mechanisms through a full description of the microstructure.

- IASCC mechanism: Improve understanding on IASCC in internals stainless steels through both experiments and analysis of decommissioned components.

- Modelling: Utilize multi-scale simulation tools to assess the microstructure and the micro-mechanical behavior of the irradiated austenitic steels in PWR conditions.

Contact:

![]() Rémi BONZOM

Rémi BONZOM

![]() +33 (0) 1 60 73 74 19

+33 (0) 1 60 73 74 19

![]() remy.bonzom@edf.fr

remy.bonzom@edf.fr

Supplemental projects

![]() SHERLOCK

SHERLOCK

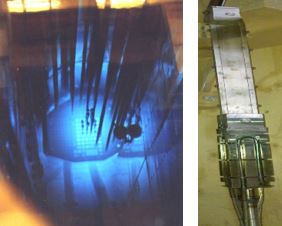

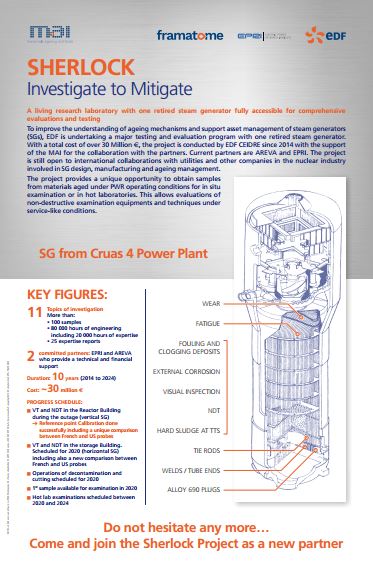

Investigate to mitigate a living research laboratory with one retired steam generator fully accessible for comprehensive evaluations and testing

Investigate to mitigate a living research laboratory with one retired steam generator fully accessible for comprehensive evaluations and testing

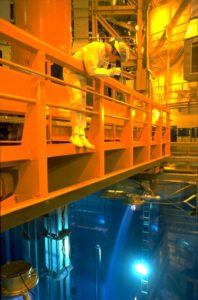

To improve the understanding of aging mechanisms and support asset management of steam generators (SGs), EDF is undertaking a major testing and evaluation program with one retired steam generator. With a total cost of over 30 Millions €, the project is conducted by EDF CEIDRE since 2014 with the support of the MAI for the collaboration with the partners. Current partners are AREVA and EPRI. The project is still open to international collaborations with utilities and other companies in the nuclear industry involved in SG design, manufacturing and aging management.

The project provides a unique opportunity to obtain samples from materials aged under PWR operating conditions for in situ examination or in hot laboratories. This allows evaluations of nondestructive examination equipment and techniques under service-like conditions.

Contact:

![]() Badre ALLOUCH

Badre ALLOUCH

![]() +33 (0) 2 47 98 67 23

+33 (0) 2 47 98 67 23

![]() badre.allouch@edf.fr

badre.allouch@edf.fr

CARBON SEGREGATION PROJECT

During conformity assessment of EPR Flamanville 3 RPV, some impact tests results were below ESPN (French Nuclear Pressure Equipment Regulation) requirements. Analyses showed those values were induced by a positive carbon segregation remaining in the part. This result led to an extensive program of characterization of both positive carbon segregation and mechanical properties to demonstrate the presence of the positive carbon segregation did not induce a fracture toughness which could question the integrity of the bottom and upper head. An analysis of which heavy components installed on the existing fleet could be concerned was performed and revealed that SG primary head forged from a conventional ingot presents also a positive carbon segregation remaining in the part. In this context, EDF and FRAMATOME are undertaking a major experimental project on positive carbon macro segregation in order to improve the knowledge on carbon content distribution in heavy forged components and the associated material properties. Organizations representing utilities, NSSS vendors and other companies in the nuclear industry are interested in this project.

During conformity assessment of EPR Flamanville 3 RPV, some impact tests results were below ESPN (French Nuclear Pressure Equipment Regulation) requirements. Analyses showed those values were induced by a positive carbon segregation remaining in the part. This result led to an extensive program of characterization of both positive carbon segregation and mechanical properties to demonstrate the presence of the positive carbon segregation did not induce a fracture toughness which could question the integrity of the bottom and upper head. An analysis of which heavy components installed on the existing fleet could be concerned was performed and revealed that SG primary head forged from a conventional ingot presents also a positive carbon segregation remaining in the part. In this context, EDF and FRAMATOME are undertaking a major experimental project on positive carbon macro segregation in order to improve the knowledge on carbon content distribution in heavy forged components and the associated material properties. Organizations representing utilities, NSSS vendors and other companies in the nuclear industry are interested in this project.

Contact :

![]() Adrien GUÉRY

Adrien GUÉRY

![]() +33 (0) 1 60 73 66 32

+33 (0) 1 60 73 66 32

![]() adrien.guery@edf.fr

adrien.guery@edf.fr

Discover the Handbook of material ageing management for nuclear reactors

Discover the Handbook of material ageing management for nuclear reactors